Harley Davidson Tech Tips

Tech Tip #5

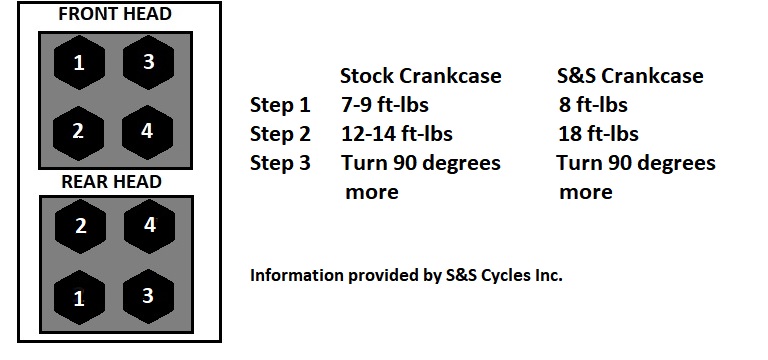

Evolution Engine – Cylinder head bolt Torque

Always work clean. Be sure the threads on the cylender head studs and head bolts are free of dirt.

Before assembly, lightly oil the threads of the head bolts (never use anti-seize compounds) so fricton will be minimized and torque values will not be distorted.

For each head follow steps in numerical bolt order then move onto next step, until all steps complete.

Engine

Tech Tip #4

A fuel map is found on a fuel injected engine. It is electronic data stored in the bikes ECU (Electronic Control Unit, a small computer)

The ECU controls the ignition timing and tells the fuel injectors how much fuel to inject at a certain throttle opening at a certain RPM.

A custom fuel map allows more or less fuel, as programmed, to optimise the power or fuel efficiency for a specific engine setup.

Sometime completed fuel maps can be downloaded, sometimes you can adjust the fual map manually by rotating knobs on the control unit. (depending on the ECU)

Options are a complete new ECU or a ‘piggyback’ controller that modifies the signal that is sent to the stock ECU so that it will deliver a different amount of fuel.

The bikes O2 or ‘Knock’ sensors give additional information to the ECU for real-time adjustment to fuel and ignition timing where necessary. (This is called a closed loop system)

Fuel & Air

Tech Tip #3

The volume of oil used for fork sliders can be found in the Manufacturers Service Manual. Fork oil is available in SAE 5, 10, 15 and 20 weight.

The higher the number, the thicker the oil.

When you have too stiff dampening in your front-end this may be solved by using a thinner grade fork oil, or thicker if not stiff enough.

Long front-ends with more rake have a reduced direct pressure on the front springs but higher friction between the tubes and sliders. It may be advantageous to decrease pre-spring pressure and/or to use a thinner grade fork oil to improve susspension. For extended front-ends the amount of fork oil used is identical to stock length forks.

Long front-ends with more rake have a reduced direct pressure on the front springs but higher friction between the tubes and sliders. It may be advantageous to decrease pre-spring pressure and/or to use a thinner grade fork oil to improve susspension. For extended front-ends the amount of fork oil used is identical to stock length forks.

Fork Tip

Tech Tip #1

How do you quickly determine if you need a 1970 to Early 1977 or a Late 1977 to 1984 Shovelhead CAM?

Measure the outer diameter of the CAM gear on the camshaft that is to be replaced.

The 1970 to early 1977 CAM will measure approx. 70mm

The Late 1977 to 1984 CAM will measure approx. 69mm. These CAM’s are not interchangeable.

The Late 1977 to 1984 CAM will measure approx. 69mm. These CAM’s are not interchangeable.

Engine Tip

Tech Tip #2

The difference between Single and Dual Fire.

Dual fire

This is the simplest system and the way the earlier, pre-Twin Cam, engines work. A single coil is used and both spark plugs fire simultaneously. The ‘wasted’ spark is sometimes said to be horsepower robbing.

Single Fire

This is the way the stock 2000-Up Twin Cam engines work. Two separate coils will fire the spark plugs independently and only the spark plug of the cylinder that is on the compression stroke will be fired. It is said that these engines vibrate less and can improve power. The effect will become more pronounced with hotter CAM’s and higher RPM.

Dual fire

This is the simplest system and the way the earlier, pre-Twin Cam, engines work. A single coil is used and both spark plugs fire simultaneously. The ‘wasted’ spark is sometimes said to be horsepower robbing.

Single Fire

This is the way the stock 2000-Up Twin Cam engines work. Two separate coils will fire the spark plugs independently and only the spark plug of the cylinder that is on the compression stroke will be fired. It is said that these engines vibrate less and can improve power. The effect will become more pronounced with hotter CAM’s and higher RPM.